Fujitsu: Authentication of components with IOTA

cryptocurrency·@keenhero·

0.000 HBDFujitsu: Authentication of components with IOTA

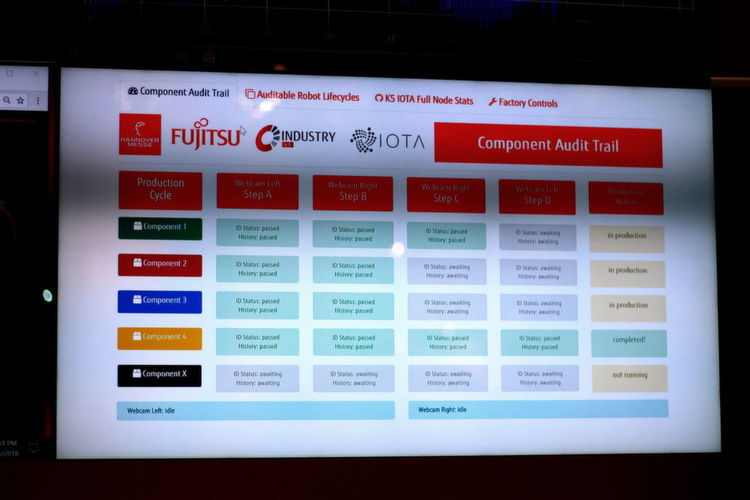

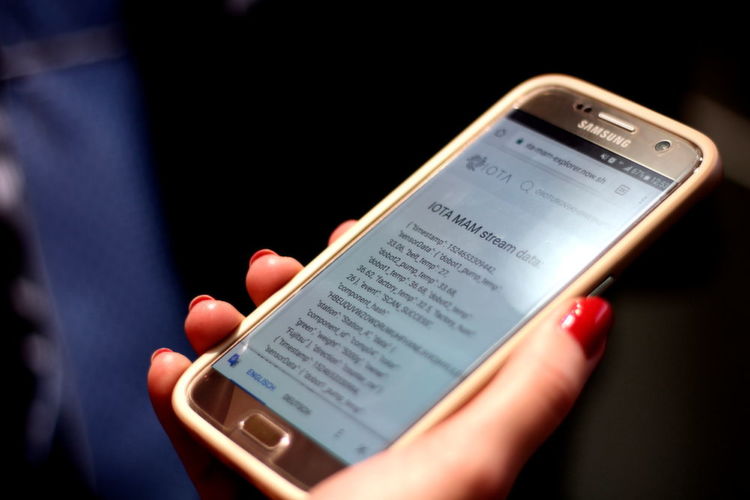

Where once more the blockchain concept had fallen, much was already turning around at the Hannover Messe 2018 for IOTA - a new payment method for the industry. The hype is great, the first companies are showing initial application scenarios - including the Japanese technology group Fujitsu. The fact that the buzzwords IoT and Tangle are in the name of IOTA is only incidentally the reason why Fujitsu already uses the technology and is convinced of its principle. The Internet of Things and Industry 4.0 play a key role at Fujitsu. In order to advance these topics, the company combined its extensive expertise in the area of industrial IoT (IIoT) and bundled it into the Industry 4.0 competence center, headquartered in Munich. Why is the Japanese engineering group using IOTA? "It's a typical IoT system: IOTA focuses on it, the disadvantages of a blockchainto address this. And especially in the industrial environment, where it often has to go fast, I can not wait for a ten-minute mining process until I know if it's an original component or not. I want the data as fast as possible, "explains Andreas Rohnfelder, Head of the Industry 4.0 Competence Center at Fujitsu. For IOTA, there are neither miners nor transaction fees. Instead, the technology offers high scalability and speed.    Big partners like Fujitsu are currently helping IOTA drive the market further and make it more attractive to the industry. At the Hanover Fair, the Japanese company demonstrated the functionality of IOTA and its use in production with a simple show case. As part of this IOTA-based audit trial, production data and transactions were stored forgery-proof and unchangeable. Secure processes across multiple factories Using two miniature robots that are representative of two factories to demonstrate how the use of the tangle - the directed, acyclic graph that forms the basis of a distributed ledger - can help identify product sorting and self-sort out. "This is a very interesting scenario for companies that rely on what they get from their suppliers as original parts that have the right quality," says Rohnfelder. In addition, it can be demonstrated with attached photos that certain components were manufactured under the same conditions and all quality controls were carried out. Already at the beginning of April 2018 Dr. Ing. Rolf Werner, Head of Central Europe at Fujitsu, welcomed as a new member of the IOTA Foundation. Apparently, Fujitsu has been using the technology for some time; The company therefore already presented the first application at the Hannover Messe.