Solar Power System with Up-cycled Components Part 2

solar·@motinkergnome·

0.000 HBDSolar Power System with Up-cycled Components Part 2

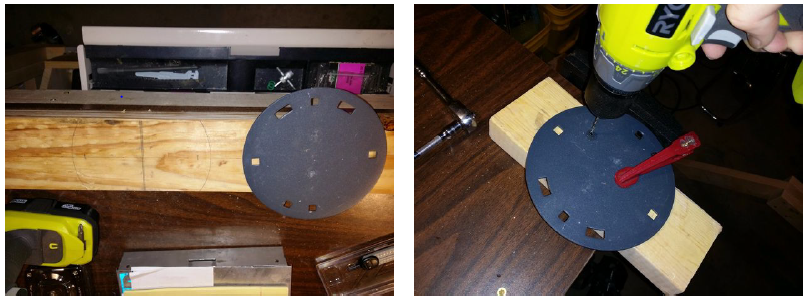

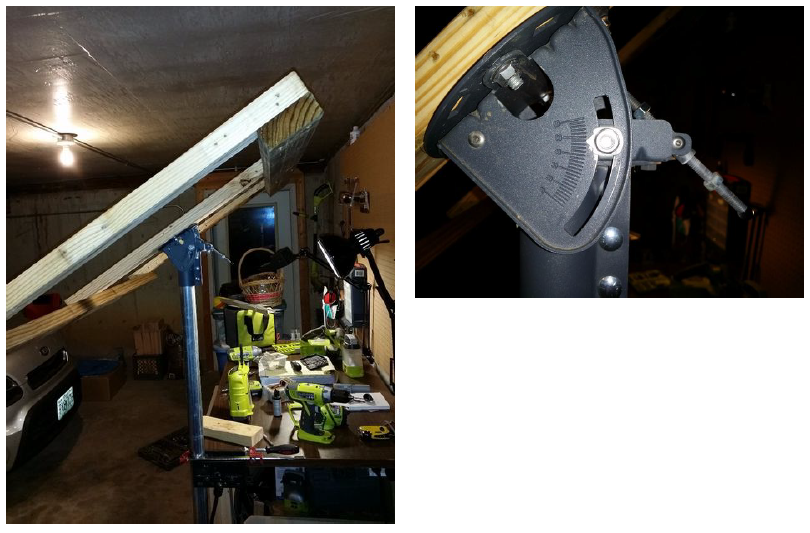

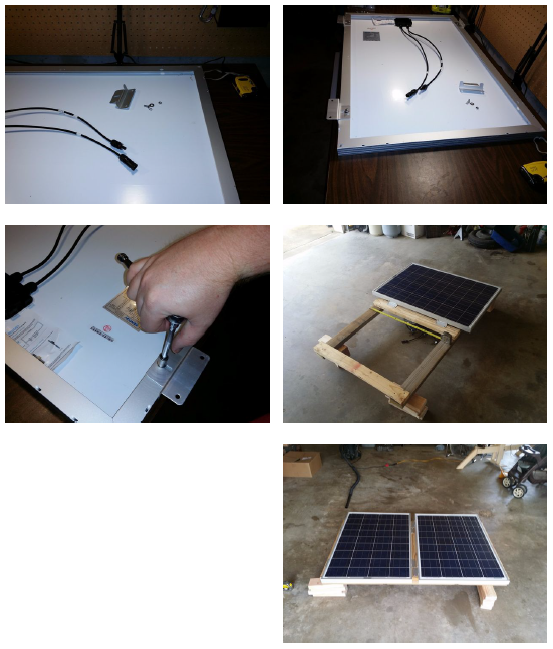

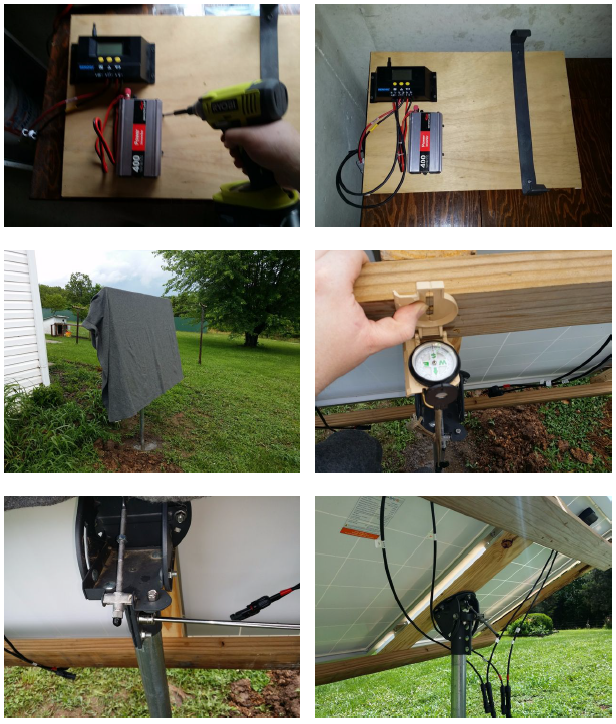

Hello, this is a continuation of part 1 posted here. https://steemit.com/steemmakers/@motinkergnome/solar-power-system-with-up-cycled-components-part-1 The following are steps 4-9 Thanks for following along enjoy. ## Step 4: Recovering the pole Once upon a time where we were in the country the only internet service was laggy satellite internet. Sure it had decent speeds once it got going but ping returns were measured in seconds. Needless to say, I ditched it as soon as there was a better alternative but I still had the pole and dish. While Taking the dish out I noticed that the pipe was some pretty stout stuff and I could hang all 250 lbs of me from the arm of the dish without the pole flexing, hey the bracket is marked to indicate the angle the dish is pointed at. I wonder if I could reuse it for my solar panels? That was my eureka moment I was now determined to get the pole out of the ground and re use the bracket with the fancy graduations to tilt my panels. The only thing was how the heck can I get it out of the ground. The short answer is that I didn't. First I unbolted the dish from the angle bracket then dug down until I hit concrete. I then used a reciprocating saw with a metal blade to cut it off as flush as possible. The resulting pole was about 5'6" including the mount. I also salvaged all the bolts and nuts, as well as the mounting plate from the back of the dish. The resulting scrap dish pieces went to the boy down the road who gathers metal to sell back to the recyclers. I gotta hand it to the kid he works hard for the pocket money he earns.  ## Step 5: Fabricating the Frame to Mount the Panels. Going with the upcycled/reused theme of this build I grabbed the long piece of 2x4 and measured it hoped that it was long enough to get 2 boards to make the top and bottom edge horizontal boards. The 3 vertical stringers only need to be as long as the Z Bracket mounting hardware. The pictures should clarify this. The following is how I made my panel rack. 1. Lay out the panels into the position they will be mounted. 2. Measure their width and length accounting for any hardware 3. Mark and cut the long 2x4 in half these will be the horizontal sections. 4. Find a pallet that has good stringers at least as long as your bracket locations on the vertical. 5. Carefully break down pallet to obtain the stringers. 6. Determine which is the best stringer and find its midpoint 7. Center the mount plate on the board and align it square 8. Mark out a pattern for screws 9. Slowly drill screw holes that are the same diameter as the shank for your 11/2 deck screws. 10. Use a drop of oil to keep the bit lubricated. 11. hold it up to the light and admire your handiwork 12. Find the center line of your horizontal supports 13. Center the middle stringer, placing the marked side down. Square it up with your protractor, and screw it using 3 2 3/4 inch deck screws in a V pattern. If on this side you are pointing down when it is flipped for the back side you will want them to point up. 14. Screw the other 2 vertical stringers ensuring that they are also square. 15. Flip the assembly over and use the same screw pattern only reversed. If the "front" had the V pointing down have the V pointing up on the "back". 16. Insert carriage bolts into the mounting disk. Then screw it into the stringer where marked. 17. Using the carriage bolts attach the pole bracket on to the mounting disk. And tighten the nuts down using an appropriate socket. At this point, I mounted the pole in my bench vise. I checked to ensure that the pipe was level in 2 directions. I then set the rack in place on the end of the pipe and checked to make sure that it was level as well. I also loosened all the angle adjustment nuts and was pleased to see that the rack was balanced enough that it did not tilt on its own accord and stayed in the position it was set in. I checked the most angle I can achieve is 60 degrees instead of the optimum 74 for the summer solstice. But the good thing is that the efficiency lost I am more than going to make up for in hours of daylight. The good news is that I can tilt my panels toward the optimum angles for the winter months when daylight is a much rarer commodity. To figure out your optimum angles of tilt from vertical the linked calculator will show you all you need to know for your location. http://solarelectricityhandbook.com/solar-angle-calculator.html      ## Step 6: Drive and Secure the Pole in Concrete. Figure out where you are going to want to sink your pole. I chose an area that Gets good sun during the summer from 10 Am - 7 PM when the trees shade that part of the house. However, in the winter the trees will lose their leaves so it will get even better sun then. Anyway on to sinking the pole. 1. I dug a hole about shovel deep, and a bit wider then a shovel and a half wide. 2. Then I centered the pole in the hole and due to the waterlogged clay, it stood on its own accord. 3. Using the short 10lb hammer I re-handled in a previous tutorial I drove the pole in about 2 and a half feet down. Using a scrap of wood to prevent the pole from mushrooming out. 4. Check level in 2 directions and lightly knock the pipe sideways to correct for any variance. 5. I mixed the concrete in accordance with the packaging, in a storage tote. 6. After mixing pour the concrete around the pole. 7. Use the hoe to tamp the concrete until it is a uniform flatness. 8. Let the concrete set according to package directions and clean your tools.    ## Step 7: Putting it all Together. This one is dirty. If you only have a cordless Hammer Drill with a dull masonry bit like I did you are going to have a bad time. Concrete dust is going to go everywhere and it will mess up your lungs so wear a mask/respirator and goggles not just safety glasses. Hearing protection too. Trust me this part sucks. 1. Put on the safety gear 2. Chuck your masonry bit into your hammer drill 3. Insert a fresh battery. 4. Start drilling the hole through the garage wall where you want to route the cables. 5. Keep drilling through 6 inches of concrete, change the battery 6. keep drilling through the 8 inches of concrete change the battery 7. hey still drilling time to Change battery 8. How thick is this wall anyway 10 inches a foot I don't know. 9. Still drilling.. 10. Finally broke through to the other side. It was 10 inches thick and I only know as I measured the bit after I was done. 11. Blow dust out of the hole using a can of compressed air or a leaf blower. Keep your mask on. 12. Insert your cables for the charge controller from the outside in. Note the red tape for the positive cable. Yes, I made a big production out of drilling the hole but it honestly sucked and I hope to never do such a thing again. I must have hit 2 or 3 rocks and possibly some rebar in ther. Due to the position of the hole I had no good way to apply some shoulder pressure to this drill. I just kept on hammering on. Now mount the panels to the rack. 1. Attach the Z brackets to the panels according to their directions using an appropriately sized socket. 2. Lay out the frame bracket side down and support it up with blocks to that it is not wobbly (2x4 tower FTW) 3. Center the first panel onto its side of the rack. Secure it using the included self-drillingscrews and an impact gun or drill driver. 4. Center the second panel and attach it in the same manner.    ## Step 8: Final Assembly Ok, this Has been a long tutorial but thanks for bearing with me. Now that the panels are mounted to the frame it is time to carry it out to the pole and finish hooking it all up. 1. I first mounted the charge controller to a small wooden book stand, that I found in a dumpster, using 1" drywall screws 2. Then I mounted the inverter by wedging the screw heads into the side fins of its chassis 2 on the long sides with 1 on the ends Not tight just to keep it secure as there are no mounting holes. 3. Then I mounted the bracket for my tool battery charger in place. 4. Finalize the hookups working from right to left. Inverter, Battery, Panels DO NOT CONNECT THE BATTERY BANK AT THIS POINT. 5. I carried the assembled PV rack out to the pole with the bracket as close to vertical as I could get it. 6. I then Used my compass to aim the rack at 180 degrees south. 7. Using a socket wrench I tightened the mounting clamp. 8. Covered the rack with a blanket to ensure that it is not generating any electricity. 9. Connect the PV panels to the cables to the Y combiner junction and fuse, the same way as the bench test instructions. 10. Connect the battery bank disconnect to the storage batteries. 11. Uncover the panels. 12. Set the panel angle according to the time of year. 13. Secure the angle adjustment. 14. Zip tie the cables to the pole, 15. Inject a bit of caulk into the hole to seal it. 16. Check the readouts to ensure voltage from the panels, battery and load. 17. Verify the amperage flowing into the storage battery. 18. Verify amperage flowing to the inverter. 19. Charge up the batteries used to build this all. 20. Enjoy the beverage of your choice while you put your tools away knowing that you are now harvesting clean energy and that your projects will now be that much better for it.   ## Step 9: The Conclusion. This was an involved project. I have learned quite a bit in actual practice to go along with all the theory and principles that I have read about over the years. I like omitting the phantom load of my Ryobi "Super Charger" and am thoroughly pleased knowing that my 7 Li-Ion battery packs are being charged via a clean power source. I have also ran the power outlet from the work bench to the inverter so that I may power my LED light fixtures from it as well while I am tinkering with easy access to grid power to run energy hog tools like my shop-vac and sander. When and If the battery bank dies, I think I am just going to replace it with a single or pair of group 29 marine deep cycle batteries. The 3 batteries that I have now only have a capacity of about 60 Amp/Hours combined. When a large deep-cycle marine battery has anywhere from 80-120 Amp/Hour Capacity. The only downside is that each battery would vary in price from $100-200. I would already have the cores to exchange so I guess I have that going for me. However, I would have to build a vented battery box as the sealed AGM batteries I have currently are spill proof and not vented. Arthur and I have been tried various experiments; shading panels, pointing them in non-optimal directions and angles, varying them from dusty to wet, all while noting the differences in voltage and amperage generated on the charge controller display. I think he is just as amazed as I was and he likes the idea of getting free electricity. Future upgrades will include replacing the battery bank as they fail before adding more solar capacity. However, it would be relatively inexpensive to add another 200W of solar. The only downside is that if I went more then 400W of solar I would need to expand to a more expensive charge controller and possibly a larger inverter. Currently 100W panels can be found for about $1.50/ watt delivered down from the $5/watt + shipping back when I started lusting after solar power. However, it is far cheaper to add conservation then it is to add capacity. If you can save 10W per light bulb that is 210W per week for 3 hours nightly run time that you would not have to collect and store in your solar system. Another thing to think about if you are concerned about atmospheric carbon and climate change. Every 1 Watt/hour of electricity saved, or generated via clean energy sources, sequesters about 500mg of atmospheric carbon. Take the 10W savings for switching a single compact fluorescent to a LED light bulb will prevent 105 grams of atmospheric carbon from being released. If I am able to use the full amount generated by my system each week, I would be able to save 5 Kilowatt Hours of electricity, 3500 Grams of atmospheric carbon, and about $.55 with my electric bill. I guess every little bit helps, so I will continue to change out CFL's with LED bulbs and replacing old power hog appliances with newer energy star rated ones. Camping and Disaster Preparedness. I tend to think of all the different ways I can use something. With a background in firefighting and emergency management, I tend to know that disasters will happen the only variable is when. So now if the power goes out my family has a back up to the grid and can run some modest loads virtually indefinitely. When I picked the tool line I wanted to go with I chose Ryobi for 2 reasons. They are affordable and there is a wide variety of tools that are interchangeable with the same battery type. Granted the lithium batteries can get expensive however I was able to maximize my battery quantity by buying refurbished lawn tools that included batteries and a tool. As such, I wound up with 7 battery packs 2 High capacity packs 4 standard capacity and one standard capacity + pack. In the event of a storm, the reciprocating saw with a tree trimming blade should make short work of 10-inch branches. wood metal and other cutting the rest of the time. The Radio also has Bluetooth audio connectivity and the ability to charge phones and other devices via the USB port. Tunes and a phone top off while working. Information, entertainment, and a way to keep connected in an emergency. The 2 x 120 lumen LED lanterns are perfect for sitting out by the fire pit camping or on the porch. Sometimes you just need to not sit in the dark. They are perfect for closing up the chickens reading at night or any other use where one may want to see in the dark. The flashlight Is even better instead of a nice area light it projects a pretty tight beam perfect for poking around under the car or trying to figure out what that noise was in the pastures. I can also charge my laptop and tether through my phone for internet providing that the cellular towers are still up. With the garage being all poured concrete It should survive some severe storm damage. And the LED light bulbs on my workbench are perfect for being run off the inverter and battery bank. So that I can set up a temporary kitchen with my butane camp stove, Alcohol Stove or good ole fashioned grill. All though I have yet to try it I should be able to run a mini-fridge that I keep in the basement family room as it is supposed to only draw 1 amp at 110v. I just don't want to hork out the fridge to the garage. But one of the long extension cords may make a sufficient test. In conclusion, I hope that my experience in installing a small solar power plant has instilled a desire to get you building if you have any questions feel free to ask I will be more than happy to help in any way that I can. Conversely if you see something that I could have done better please point it out.  Oh and full disclosure I am not sponsored by any company or entity. I my endorsement of Ryobi is just because I like their stuff. I have since added a 40v Ryobi chainsaw to the mix that my solar set up charges as well. I just like there stuff and the interchangability makes it easy for me. :)

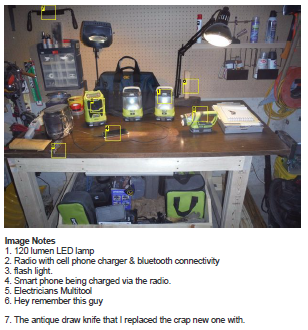

👍 danyflores, motinkergnome, wolfeblog, texasoffgrid, drmake, sensation, steemmakers, jefpatat, atim1234, salvadorcrg, pbock, simplylizelle, dante31, smithlabs, seyiodus, orracle, itestify, enm, livesustainably, aisu, zevron, anomadsoul, promo-mentors, dragondance24, raj808, futurethinker, umar97, tpkidkai, dedicatedguy, trufflepig,