4D PRINTING: THE DRAMATIC 3D

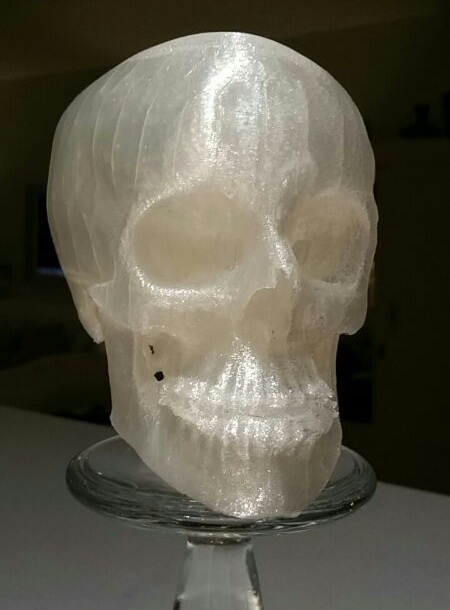

technology·@sparklez·

0.000 HBD4D PRINTING: THE DRAMATIC 3D

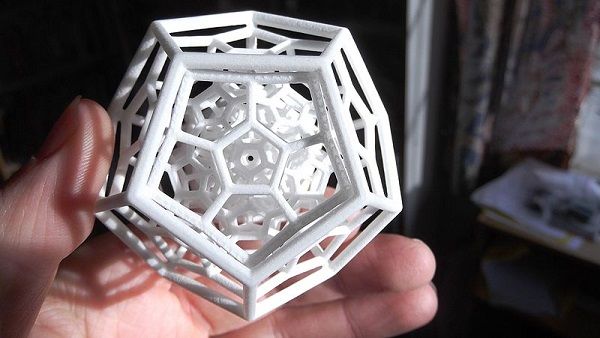

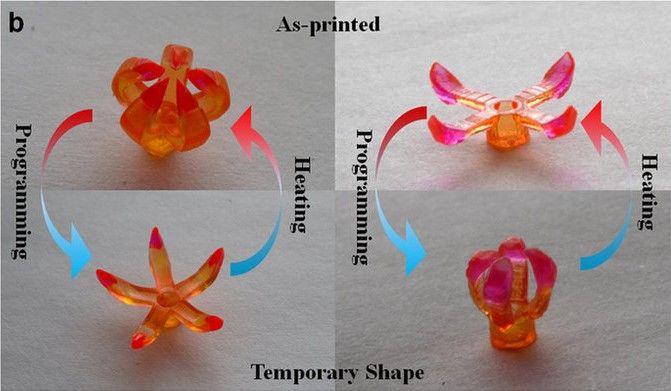

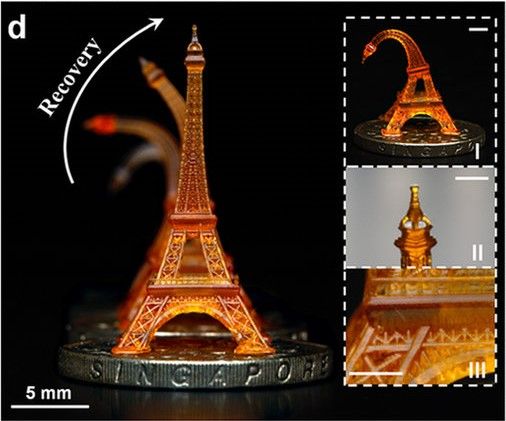

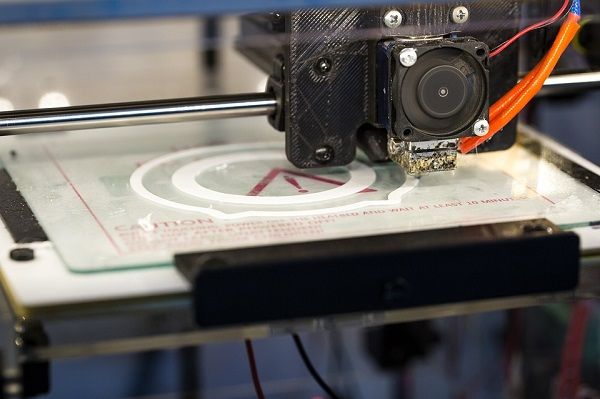

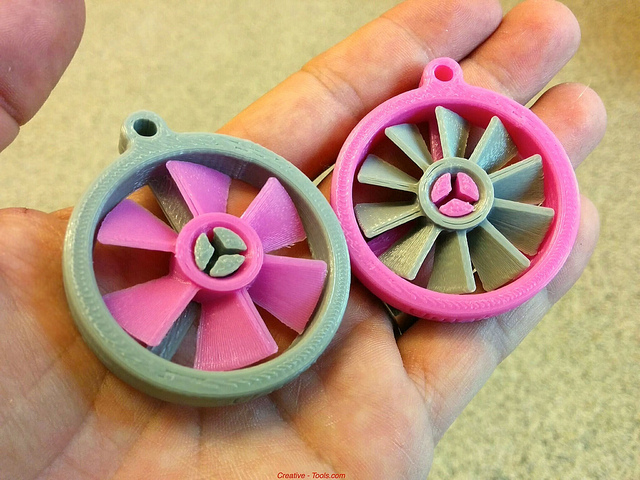

## Hello Amazing Steemians, its sparklez ###### <div class="pull-center"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:3D_printed_object_-_Flickr_-_brewbooks.jpg" rel="noopener">By Brewbooks CC-BY-SA-2.0, via wikimedia commons: a 120-cell 4D polytope</a></em></center></div> Have you ever wondered trying to get a product or a home appliance and right there and there, it is printed without taking much of your time and way lesser? As a grown up, I always wished I could just replicate a particular gadget or device because I love gadget, something they could just do a copy and paste for. Well, say hello to 3D printing. A 3 Dimensional printing could be referred to materials joined or solidified using computer control it, creating a three-dimensional object with material being added together (such as liquid molecules or powder grains being fused together). 3D printing can be used in both additive manufacturing (AM) and rapid prototyping. Objects created can take any shape or geometry and they are produced using digital model data from a 3D model or another electronic data source such as an Additive Manufacturing File (AMF) file (usually in sequential layers). We always heard of 3D Printing, which involves creating a three dimension from a digital file to become a solid object that can be felt with the hand. Imagine a world where you could just print out what you need, even the printing of food…wow! Yeah you need to believe that even if it sounds unbelievable. ###### <div class="pull-right"><center><img src="https://steemitimages.com/0x0/(https://steemitimages.com/DQmYnMTgynv9JQtiPwquRCvD5vrp49peSHsyyL2icqxMyb2/8680902302_09b006da44_z.jpg))" /><br /><em><a href="https://www.flickr.com/photos/pestoverde/16862208982" rel="noopener">by Maurizio Pesce via flickr creative commons: ChefJet Candy 3D Printer </a></em></center></div> If not for the research of this printing technique, I wouldn’t know this. A company called *Natural Machines* has made food printing possible with a machine called the “Foodini”, a machine that works just like the 3D printing machine but instead of the materials used by the 3D Printers, the foodini uses edible ingredients coming out of a stainless steel capsules. Now, your brains are opening and thinking of other things it could print, and before you go further…boom! Let me introduce you to the 4D Printing…now printing technology is off this world. Have you heard of a 4D printing? Just when you thought it ended in the 3D printing. A 4D printing is a new dimension incorporated into the printing world. The 4D is an idea to print structures, objects that are able to change and morph after printing. When I say Morph, I mean something that could change smoothly from one form to another in the case of 4D printing. The term 4D was first designed and pioneered by the co-director and founder of the Self-Assembly Lab at MIT’s (Massachusetts Institute of Technology) International Design Center by name Professor Skylar Tibbits in the field of 4D Printing. The Self-Assembly Lab lays emphasis on self-assembly and programmable material technologies for manufacturing, construction processes and products. ###### <div class="pull-right"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:4D_Printing_-_time-lapsed.jpg" rel="noopener">Authours: Qi Ge, Amir Hosein Sakhaei, Howon Lee, Conner K. Dunn, Nicholas X. Fang & Martin L. Dunn via wikimedia CC-BY-4.0: Demonstration of the transition between as printed shape and temporary shape of multimaterial grippers</a></em></center></div> The 4D would definitely be significant for manufacturers and printers because the printed objects exhibit robotics-like behavior, and to make it interesting, they don’t require complex and expensive electro-mechanical components to work. The use of special gels that change and react with certain stimuli are used, because the gel’s behavior is predictable, since researchers already know how printed structures will behave. Some of the materials helps the 4D printed object to change over long stretches of time, while some changes occur immediately on the print bed. The 4D printing are just 3D printing with higher technology, a 3D printing that could curl, stiffen and fold like plants that are just growing when seen from a time-lapse video. The fact is that technology is advancing every day. Every day, new things are developed. The 3D is “Three Dimension”; 4D is “Four Dimension”; which means you can see an object in a four dimensional angle. It is said that 4D printing mimics the way and how calla lilies, Orchids and other plants twists and bends. Apparently, plant structures are made up of fibres known as [cellulose]( https://en.wikipedia.org/wiki/Cellulose) and these fibres can be controlled in the direction in which they were oriented within the printed structure. And in turn, these fibres orientation manipulate the way in which structures swell when water is applied. ## The Scope Behind 4D Printing ###### <div class="pull-left"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:4D_Printing_-_eiffel_tower.jpg" rel="noopener">Authours: Qi Ge, Amir Hosein Sakhaei, Howon Lee, Conner K. Dunn, Nicholas X. Fang & Martin L. Dunn via wikimedia CC-BY-4.0: 3D printed SM Eiffel tower</a></em></center></div> The 4D printing creates a 3D object, but this time, it changes in shape in response to stimuli, such as light, heat or moisture. If we are familiar with the Boolean Algebra, which has a question like ‘are both inputs 1s?’ or “is either input a 1”? same question was asked by the Tibblet Lab, using complex polyhedrons rather than 1s and 0s, representing state used by the usual electrical on/off. The input involves shapes clicking into place and this creates a new configuration that enables the next shape-the output-to attach only in an upward (time) or downward (false) orientation. 4D involves rigid and expandable materials close to each other with one 3D component. When the expandable material come in contact with water, they increase in volume more than their original volume, this changes their shape and repositions the rigid materials by the side. This is activated by different environment and in turn takes different form. Depending on the material used for the design, the contact substance used are different; it could be water, heat, light or simple energy. When designing or building this, software is used to design/program on screen before the object is created. Over the years, researchers move with geometric shapes. Have you ever tried making or carving something out from a cardboard or a metal; it is very likely to fold readily the way you want it first. Ok! But instead of that wood, metal or the cardboard used, a combination of materials can be used, in which some of the materials can absorb water and develop while the rest retains its stiffness. Put the material in water and watch its shape change, but before achieving this, lots of precise control are needed over the materials and the pattern of your machine laying the materials down. ###### <div class="pull-left"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:Jewelry-3d-pringint.jpg" rel="noopener">image by Irwikilord (own work) via wikimedia CC-BY-SA-4.0</a></em></center></div> With the help of Physics and advanced technology, researchers were able to know the right fold for the material, getting inspiration that plants have provided. For example, plants tend to bend towards sunlight because sunlight kills hormones called auxims that encourage growth. So a plant that has its side away from the sun grows faster than the side facing the sun and this makes the plant bend towards the light. So researchers bend the physics in materials, energy and environment to their favour. https://youtu.be/f-49ldlkjNQ [credit](http://www.demagazine.co.uk/architecture/can-4d-printing-be-a-game-changer-in-architecture) I can’t really explain now the step by step process that the 4D printer prints its object, but it uses Stereolithography used in 3D printing technique but ultraviolet light is used after printing is completed to set layered materials. Engineers/researchers who do 4D would be used to Anisotropy, a technique used in getting the direction and magnitude of transformations by a given material under a set condition. It is done by arranging the micro materials in such a way that there is embedded direction to printed object. The hydrophilic elements and non-active, rigid element are polymer produced by Skyler Tibbits and the group at the Assembly Lab, that allows up to 150% swelling of some part when inserted in water after printing and the rigid element as the name implies sets the angle on structure constraints for the object. ###### <div class="pull-right"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://pixabay.com/en/printer-3d-print-3d-printing-white-2416269/" rel="noopener">by Ippicture via pixabay creative commons</a></em></center></div> Studies too were done for the temperature and the humidity change that allows the object to roll and unroll in shape, allowing a reversible process. In the help of building a perfect object, a software called *PROJECT CYBORG*. This is a platform used for designing, it operates in the browser and includes cloud-native simulation that can be used for self-assembly and programming materials and even optimizing multi-variable design constraints. This software allows specialized design by individuals. In a short, the software is used for modelling, simulation and multi-objective design optimization ###### <div class="pull-left"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:3D_Printed_Macrognathism.jpg" rel="noopener">by Nevit Dilmen (own work) via wikimedia CC-BY-SA-3.0: D Printed human skull. Transparent PLA. Data from computed tomography. Patient showing Macrognathism. Height was scaled to 10cm. Print resolution 200 micron</a></em></center></div> ## 4D Materials Below are some of the materials used to get the workdone - Rattered Hydrogels – This can shape-shift, when they swell - Elastomers – Activited by pneumatic or hydraulic means - Polymers – Electroactive Polymers, Thermo-reactive Polymers, Shape-memory Polymers (SMPs), Thermal Photo-reactive Polymers - Silicone Material ## Applications of 4D Printing *Medical -* 4D printing can be used to form a drug delivery device, using the body temperature as a trigger, the drug is released at any sign of fever. 4D printing has multiple application which includes the nanotechnology which could be used to print skin, print slices of liver and other organs. 4D printed proteins could be very useful as a self-reconfiguring protein. ###### <div class="pull-right"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://www.flickr.com/photos/creative_tools/15579667540" rel="noopener">by Creative Tools. flickr creative commons: 3D-printed Propeller Keychain</a></em></center></div> *Transportation -* Using a programmable carbon composites and custom wood grain, a morphing car was designed, that operates non-mechanically. 4D printing can be used to design or manufacture morphing cars. structures and components made of them changes shape in response to an entity different environmental changes in air pressure, temperature or other factors. 4D printing could be the future technology as it could replace motor, hinges or even hydraulic actuators and planes could be simpler and lighter in weight. They can also be used for roads too, which self-heal potholes. ###### <div class="pull-right"><center><img src="https://steemitimages.com/0x0/.jpg))" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:XYZprinting_inBloom_Dress_3D_Printed_Outfit_(16837487086).jpg" rel="noopener">by Maurizio Pesce CC-BY-2.0 via wikimedia creative commons: XYZprinting inBloom Dress 3D Printed Outfit</a></em></center></div> *Clothing -* The 4D printing can be used or applied in the clothing line were footwear and clothes, alter their change and function. e.g. cloths could adapt to the size or contours of the wearer which mean I could just get a 4D printing of any shoes without worrying about my size and it just morphs or we could say adapt to my leg size; isn't that cool? Or shoes that changes to waterproof when it is raining or react or react to external atmospheric conditions different from the present one. We could even see some military clothing that camouflages, insulate or/and cool soldiers when met with different input environments ###### <div class="pull-left"><center><img src="https://steemitimages.com/0x0/)" /><br /><em><a href="https://commons.wikimedia.org/wiki/File:Wooven_Table_printed_on_a_BigRep.jpg" rel="noopener">by BigRep CC-BY-2.0 via wikimedia creative commons: Wooven Table printed on a BigRep</a></em></center></div> *Home Appliances -* It can also be used to print some home appliances in the house such as fold-able chairs, tables, doors, etc. *Architecture -* imagine having a 4D printed roofs, then architectures won’t be worried about opening a leaking roofs, caused by weather conditions, as the roof will morph when exposed to a different weather or climatic condition With technology like this, you could freely play with any design you want, different materials can be used, combined with different technique. You would understand with me that the 4D Printing technology is a shooting star in the technology world as it will go a long way to ease stress. Issues that involve broken pipes in the home, that greatly needs the attention of a plumber and in the process will spend lots of cash, imagine if we had pipes that could possibly heal or repair themselves once broken or cracked, due to the ability of the pipes material to change in respect to the environments change. Just imagine the possibility? Imagine if we had a self-assembly furniture, that could curl up into a chair by adding water or light. They could go on to perform a lasting solution in building bridges, shelters, roads and any other kind of installation as the tend to rebuild themselves or repair in case there is weather damage. The 4D printing could as well solve the issue of space because it can change shape, unfold or shrink. With the advancement and evolution in technology, the 4D printing will create a very great impact in the society. ### References [Newscientist](www.newscientist.com/article/2127713-4d-printing-makes-objects-that-assemble-themselves-when-heated/amp/) [Science Howstuffworks](https://science.howstuffworks.com/amp/4d-printing4.htm) [Knowledge Ulprospector](https://knowledge.ulprospector.com/5423/pe-multi-material-4d-printing/) [Spilasers](http://www.spilasers.com/news/4d-printing-introduction-overview/) [Sculpteo](https://www.sculpteo.com/blog/2017/10/25/4d-printing-a-technology-coming-from-the-future/) [Autodesk: Project Cyborg](https://www.autodeskresearch.com/projects/cyborg) [CNN](https://edition.cnn.com/2014/11/06/tech/innovation/foodini-machine-print-food/index.html) [Skyler Tibbits](https://en.wikipedia.org/wiki/Skylar_Tibbits) [Wikipedia](https://en.wikipedia.org/wiki/Four-dimensional_printing) ## Thank you for reading

👍 sparklez, sparkosonic, gloglo, theheralds, we-are-nigeria, mustard, sensation, we-are-africa, snowyknight, greenrun, we-are-one, akpos, enugu-steem, gee1, setapart, uniquegem, steememblem, wisequote, jblsignature, uniqueknowledge, simplicitytech, doncharleshill, emjoe, spark92, joeycrack, technology-trail, techtek, egetex, steemstem, lemouth, followbtcnews, odic3o1, joseg, felixrodriguez, simplifylife, mayowadavid, erodedthoughts, enzor, ifartrainbows, physics.benjamin, robotics101, tristan-muller, sco, adetola, rharphelle, jlmol7, mittymartz, terrylovejoy, rionpistorius, heajin, ajpacheco1610, anyes2013, effofex, count-antonio, de-stem, ari16, beautyinscience, anarchyhasnogods, abigail-dantes, mountain.phil28, jamesbarraclough, deutsch-boost, jaycem, flinter, biomimi, justtryme90, dysfunctional, lafona-miner, leczy, ertwro, borislavzlatanov, juanjdiaz89, thevenusproject, dna-replication, curie, jamhuery, awesomianist, markangeltrueman, tantawi, aboutyourbiz, cryptokrieg, zacherybinx, justdentist, birgitt, kerry234, spectrums, xanderslee, speaklife, chimtivers96, responsive, ihsan19, heriafriadiaka, dyancuex, pacokam8, jacalf, keshawn, locikll, howtostartablog, slickhustler007, makrotheblack, churchboy, helgapn, krazypoet, karyah1001, gabox, infinitelearning, circleoffriends, artepoetico, esaia.mystic, crescendoofpeace, yourmercury, strings, kimp0gi, sissyjill, wrpx, fibrefox, blockmountain, ninjace, hendrikdegrote, dashfit, sethroot, brobear1995, lrsm13, mahdiyari, muliadi, runningman, snowpea, smafey, marialefleitas, bobdos, rasamuel, cordeta, laritheghost, wanderingdanish, aaronteng, debbietiyan, amirdesaingrafis, phaazer1, chillingotter, anwenbaumeister, jgpro, galberto, onethousandwords, zanoni, jordanx2, meetmysuperego, cerventus, giddyupngo, jpmkikoy, caitycat, niouton, christianschmidt, sireh, zalandir, musicayfarandula, gwys, jsf, victorcovrig, rafaljakobsen, trisolaran, zeeshan003, the-devil, pangoli, kushed, sakura1012, alexdory, foundation, serylt, medicnet, communityisyou, himal, pearlumie, pharesim, drkomoo, lamouthe, lenin-mccarthy, pseudojew, ugonma, rachelsmantra, dexterdev, mrs.agsexplorer, grandpere, nitesh9, ovij, akeelsingh, kerriknox, star-vc, gra, neneandy, suravsingh, rockeynayak, whileponderin, rjbauer85, kryzsec, sci-guy, amavi, dber, steem-id, velourex, steemedia, cebymaster, cotidiana, robertvogt, dreamien, gentleshaid, blessing97, kenadis, carloserp-2000, hadji, bue, hatuvera, jdc, wdoutjah, mindscapephotos, damzxyno, spederson, michelios, thinknzombie, happychild, benleemusic, positiveninja, parakazan, guchtere, cgbartow, coloringiship, jaeydallah, bennettitalia, steepup, drakkomaximo1234, hillaryaa, peaceandwar, kieranpearson, delph-in-holland, haarshan36, fidelpoet, dynamicrypto, warpedpoetic, genoner, bob-elr, desmonddesk, steemitboard, we-are, florae, altherion, ehiboss, smallville, leadent360, eriq, perlo, aamin, ballerz, masterwriter, mrbreeziewrites, mrxplicit, tking77798, pmduy, mcw, arrrados,